Advertisement

-

Published Date

January 25, 2023This ad was originally published on this date and may contain an offer that is no longer valid. To learn more about this business and its most recent offers, click here.

Ad Text

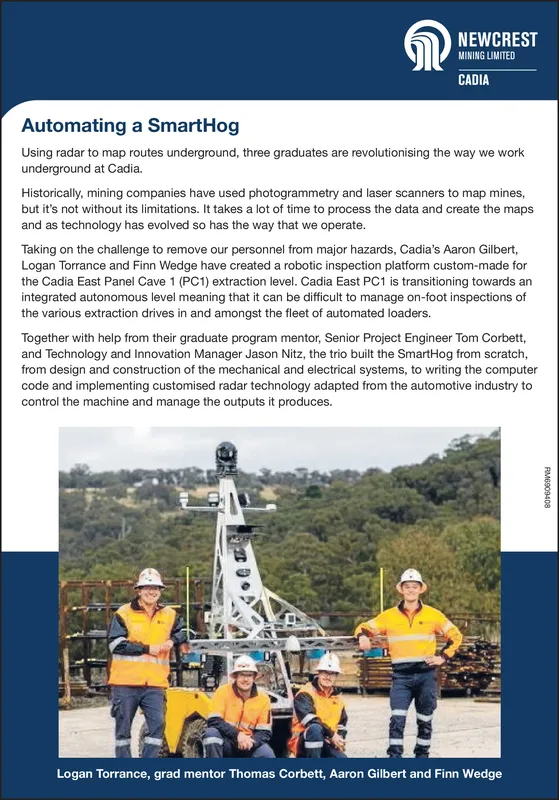

NEWCREST MINING LIMITED CADIA Automating a SmartHog Using radar to map routes underground, three graduates are revolutionising the way we work underground at Cadia. Historically, mining companies have used photogrammetry and laser scanners to map mines, but it's not without its limitations. It takes a lot of time to process the data and create the maps and as technology has evolved so has the way that we operate. Taking on the challenge to remove our personnel from major hazards, Cadia's Aaron Gilbert, Logan Torrance and Finn Wedge have created a robotic inspection platform custom-made for the Cadia East Panel Cave 1 (PC1) extraction level. Cadia East PC1 is transitioning towards an integrated autonomous level meaning that it can be difficult to manage on-foot inspections of the various extraction drives in and amongst the fleet of automated loaders. Together with help from their graduate program mentor, Senior Project Engineer Tom Corbett, and Technology and Innovation Manager Jason Nitz, the trio built the SmartHog from scratch, from design and construction of the mechanical and electrical systems, to writing the computer code and implementing customised radar technology adapted from the automotive industry to control the machine and manage the outputs it produces. Logan Torrance, grad mentor Thomas Corbett, Aaron Gilbert and Finn Wedge RM6909408 NEWCREST MINING LIMITED CADIA Automating a SmartHog Using radar to map routes underground , three graduates are revolutionising the way we work underground at Cadia . Historically , mining companies have used photogrammetry and laser scanners to map mines , but it's not without its limitations . It takes a lot of time to process the data and create the maps and as technology has evolved so has the way that we operate . Taking on the challenge to remove our personnel from major hazards , Cadia's Aaron Gilbert , Logan Torrance and Finn Wedge have created a robotic inspection platform custom - made for the Cadia East Panel Cave 1 ( PC1 ) extraction level . Cadia East PC1 is transitioning towards an integrated autonomous level meaning that it can be difficult to manage on - foot inspections of the various extraction drives in and amongst the fleet of automated loaders . Together with help from their graduate program mentor , Senior Project Engineer Tom Corbett , and Technology and Innovation Manager Jason Nitz , the trio built the SmartHog from scratch , from design and construction of the mechanical and electrical systems , to writing the computer code and implementing customised radar technology adapted from the automotive industry to control the machine and manage the outputs it produces . Logan Torrance , grad mentor Thomas Corbett , Aaron Gilbert and Finn Wedge RM6909408